Ion beam technology’s flexible, and highly configurable, system makes it one of the most widely used process solutions today.

Ion beam technology has been in demand for years now – especially when it comes to etching processes. This article will discuss the benefits and common applications of using ion beam technology and how it has changed a variety of industries.

What is Ion Beam Technology?

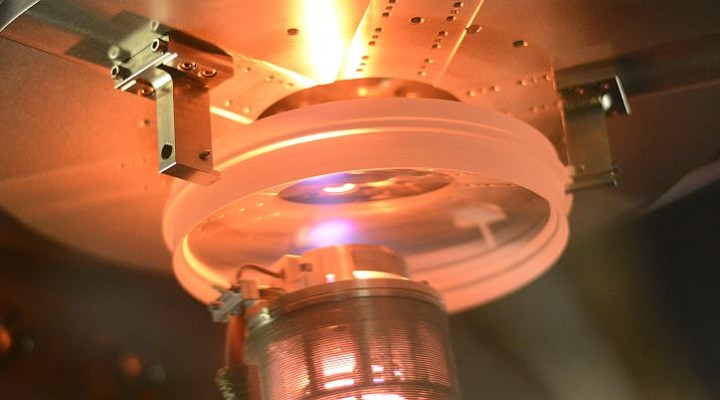

Let’s start with the basics. An ion beam source is essentially a source of plasma that has a set of grids that allows for the extraction of a stream of ions. Now, there are three main parts of the ion beam source – the grid, the neutralizer, and the discharge chamber. Each section works in conjunction with one another to produce a quality ion beam source for the process.

The Benefits

Now, ion beam etching allows for numerous benefits. For instance, all types of materials can be etched by using an ion beam source – including materials that aren’t of plasma nature. It also provides outstanding uniformity, versatility, and independent ion beam energy and current control. This allows the technician to perform any etching process with ease and solid consistency. And, when it comes down to it, these factors matter the most.

In conclusion, sputtering systems that can produce an ion beam source are becoming more in demand when it comes to the etching process. This type of technology has enhance numerous industries and has helped produce solid products. Moreover, the future is bright for ion beam technology, and it’s only a matter of time before it excels beyond expectations.

Denton Vacuum, LLC can help you find a durable and effective vacuum evaporation system for all your deposition needs.