E-Beam evaporation produces high-quality coatings and provides major benefits to the process.

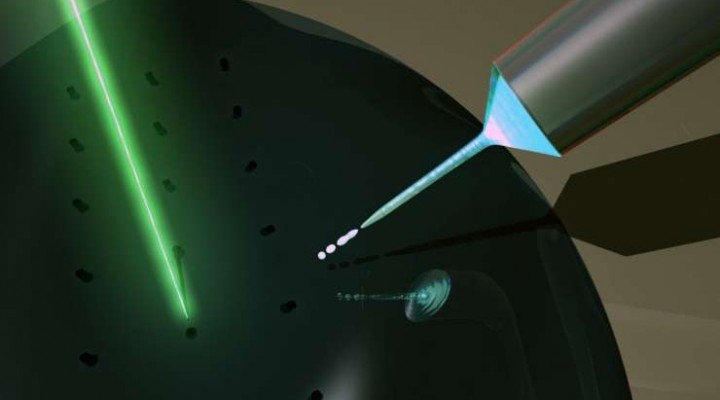

E-Beam evaporation or Electron Beam Evaporation is a type of Physical Vapor Deposition in which the material to be utilized as a coating is essentially bombarded with an electron shaft from a charged tungsten fiber to vanish and change it to a vaporous state for the material to be covered. Occurring in a high vacuum chamber, these particles or atoms in a vapor stage then produce and shape a thin film covering on the substrate.

What is E-Beam Evaporation?

E-Beam Evaporation, which is a Thermal Evaporation process, and Sputtering are the two most basic sorts of Physical Vapor Deposition or PVD. Of these two procedures, E-Beam Evaporation has a few clear focal points for application purposes – as compared to plasma-enhanced chemical vapor deposition.

Advantages

It allows the immediate exchange of vitality with the Electron Beam to the objective material to be dissipated making it perfect for metals with high liquefying focuses. E-Beam Evaporation can yield essentially higher testimony rates – from 0.1 nm for every moment to 100 nm for each moment – bringing about higher thickness film coatings with an expanded grip to the substrate.

E-Beam Evaporation likewise has high material usage effectiveness contrasted with other PVD forms lessening costs. The E-Beam just warms the objective source material, not the whole pot, bringing about a lower level of defilement from the pot. By focusing the vitality on the objective instead of the whole vacuum chamber, it decreases the likelihood of warmth harm to the substrate.

Denton Vacuum, LLC carries the finest PECVD equipment for any deposition process. For more information, visit them online today.